Overview

When smoke enters the chimney for discharge, white mist is generated at the smoke outlet, causing visual pollution.

The reason for the formation of white mist is that the moisture content in the flue gas is high and saturated. If the temperature further decreases, it will precipitate in the form of tiny droplets, causing visual white mist.

Concrete measure

Steam heater SGH: uses low-pressure steam as the heat source to heat the clean flue gas;

GGH: It uses high-temperature flue gas to heat and purify the flue gas before entering the desulfurization tower, including water-based GGH (MGGH).

Steam heating treatment method

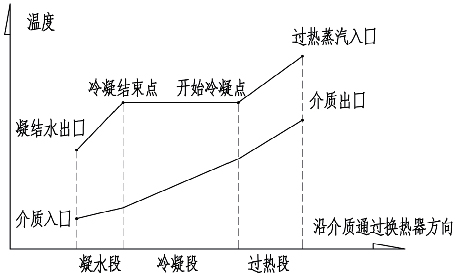

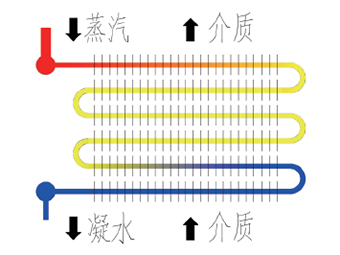

A steam heater is a typical tubular steam gas heat exchanger that utilizes the temperature difference between cold and hot fluids to heat the flue gas using the heat in the steam.

Mainly utilizing the latent heat of saturated steam and the sensible heat of condensed water. The latent heat is the heat difference caused by the condensation of saturated steam into saturated water. The saturated condensed water continues to cool down into supercooled water, and the heat generated in this part is the sensible heat of the condensed water, which is recovered after being discharged from the heat exchanger.

Working principle of steam heater

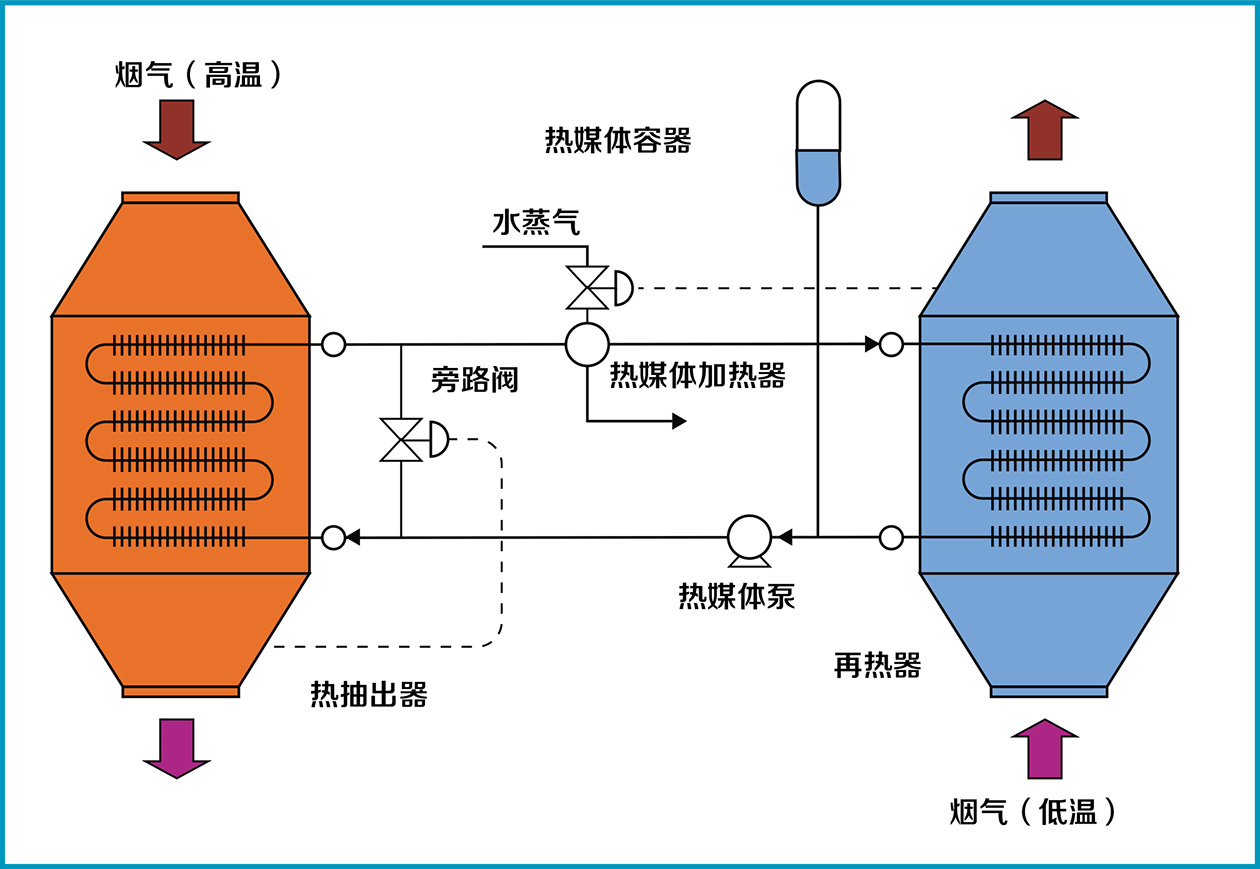

MGGH processing method

The MGGH system is equipped with two stages of MGGH flue gas heat exchangers. A flue gas cooler is installed in front of the desulfurization absorption tower, and a flue gas heater is installed at the net flue gas outlet after desulfurization.

After entering the flue gas cooler, the heat is transferred to the heat medium water. The heated heat medium water is sent to the flue gas heater. After heating the clean flue gas, the heat medium water is pressurized by the heat medium booster pump before entering the flue gas cooler. The heat medium water forms a closed cycle.

When the temperature of the flue gas in front of the tower is low, steam is used to heat the heat medium water and supplement the heat.

Medium water flue gas heater system (MGGH)